- We work with global industries!

- marketing@grihalaxmimetal.com

- +91 9060364808

- +91 8050582063

Grihalaxmi Group of Industries, founded by Mr. Maruti Kono in the year 1989 with a vision to develop quality products in the foundry sector. One of the leading industries from foundry hub of India i.e. Belgaum.

Accredited with ISO 9001:2015 & Pressure Equipment Directive 2014/68/EU certification by TUV SUD to ship our pump & valve components directly to European countries.

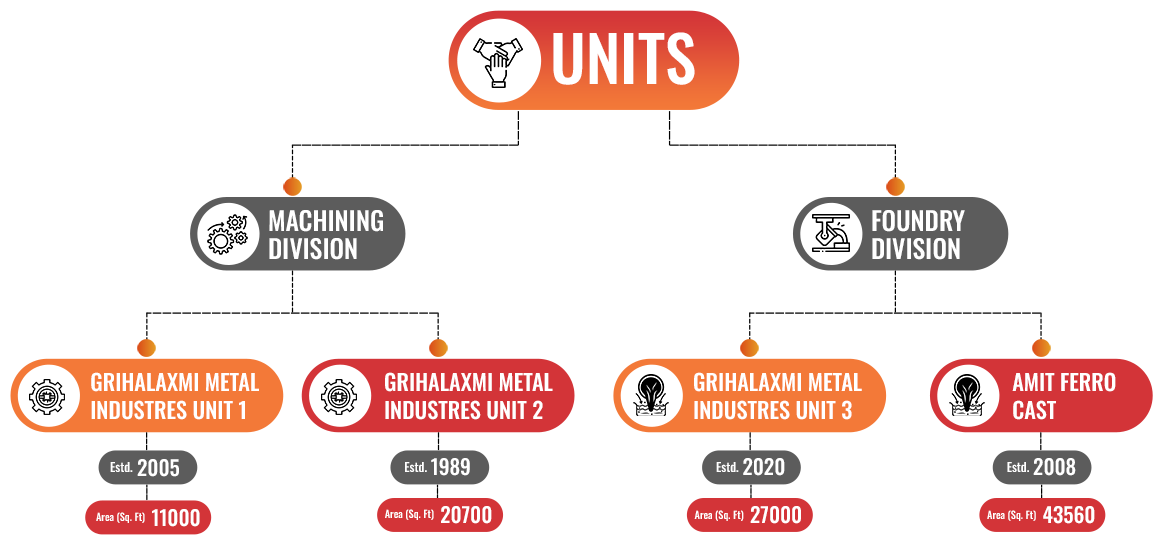

| MACHINING DIVISION | FOUNDRY DIVISION | |||

|---|---|---|---|---|

| FACTORIES | GRIHALAXMI METAL INDUSTRIES UNIT 1 | GRIHALAXMI METAL INDUSTRIES UNIT 2 | GRIHALAXMI METAL INDUSTRIES UNIT 3 | AMIT FERRO CAST |

| Year of Establishment | 2005 | 1989 | 2020 | 2008 |

| Area | 11,000 (Sq. Ft.) | 20,700 (Sq. Ft.) | 27,000 (Sq. Ft.) | 43,560 (Sq. Ft.) |

| Capacity | Approx. 960000 Pieces / Annum | Approx. 480000 Pieces / Annum | 6000 (MT / Annum) | 4800 (MT / Annum) |

| Box Size (mm) | NA | NA | 600*700*200 [ARPA 450 Moulding Line] | 450*450*150/200/250 (Min) 1500*1500*250 (Max) 1829*1829*300ARPA 300 Moulding Line & Hand Moulding. Continuous core mixer, PEP-SET core process & continuous core oven. |

| Weight | 5 Kg to 70 Kg | 5 Kg to 400 Kg | CI – 5 to 120 Kgs & DI – 5 to 120 Kgs | CI – 5 to 900 Kgs & DI – 5 to 800 Kgs |

| Grades | CI & SGI | CI & SGI | FG200 to FG300, SG400/12 to SG 700/2, EN-GJS-400/18LT, NI HARD-4 | FG200 to FG300, SG400/12 to SG 700/2, EN-GJS-400/18LT, NI HARD-4 |

We manufacture castings with Nickel, Copper, Chromium, Molybdenum & few other alloy additions as per customer's requirement.

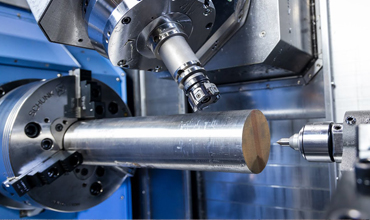

Our group has a blend of 2 semi-automatic foundries & 2 sophisticated machine shops which enables us to provide fully machined & ready-to-use components to our valued customers.

Our group specializes in the fastest component development from design to sample submission right-first-time.

Specialized in pumps & valves components; certified with ISO 9001:2015 & Pressure Equipment Directive 2014/68/EU by TUV SUD. We manufacture castings with weight range starting from 5 kg going up to 900 kg in cast iron & 5 kg going up to 800 kg in ductile iron.

Sophisticated fully equipped testing laboratory for sand testing, mechanical properties, chemical properties, etc.

Our group is supported by highly skilled & dedicated workforce that is prepared to take on any challenges as per the needs of customer with change in time. In particular, the critical components for which the customers are starving can be developed at Grihalaxmi Group of Industries.

Capacity Enhancement - Expansion of existing foundry unit with 3000 MT / annum of additional facility with ARPA 900 moulding line & additional HMC’s, VMC’s & VTL’s.